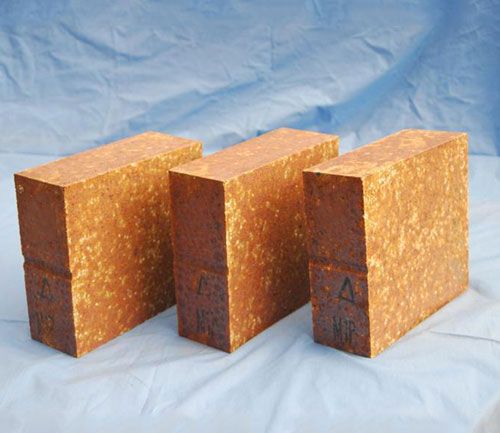

Feature:

High strength, high wearing-resisting at high temperature state, low thermal conductivity, strong thermal shock stability, etc.

Made of the high grade bauxite clinker as the aggregate, adding the BFA,SiC, ɑ-Al2O3 fine powders in the substrate, through the reasonable proportion of the particles,high pressing, high temperature sintered.

Mainly used in the lower transition zone of the cement rotary kiln,the outer surface temp. Of the rotary kiln body bring down evenly about 80℃ comparing to the magnesia-Spinel refractory brick, bring down evenly about 40℃ comparing to the traditional 1650,1680 Si-Mullite refractory brick. It is the ideal refractory brick used in the lower transition Zones of above new type of dry method 5000 TPD cement plant.

|

ITEM PROPERTY |

Large Cement Kiln Silicon Carbide Refractory Brick HXSM-01 |

Large Cement Kiln Silicon Carbide Refractory Brick HXSM-1650 |

Large Cement Kiln Silicon Carbide Refractory Brick HXSM-1680 |

|---|---|---|---|

|

Al2O3 % ≥ |

67 |

63 |

65 |

|

SiO2+SiC % ≥ |

25 |

35 |

30 |

|

A. P. % ≤ |

|

20 |

22 |

|

B. D. g/cm3 ≥ |

2.50 |

2.55 |

2.65 |

|

C. C. S. (MPa)≥ |

120 |

90 |

85 |

|

T. S. R. (1100℃ Cool water) times ≥ |

25 |

10 |

12 |

|

R.U.L.@0.2MPa Ta ℃≥ |

1670 |

1600 |

1650 |

|

Refractoriness ℃≥ |

1790 |

1790 |

1790 |

|

T. C.. (1000℃) W/m*K ≤ |

1.80 |

2.5 |

2.3 |

|

Wearing Resisting Rate (cc ) |

8.4 |

8.2 |

7.8 |

*They are typical values in this table, not a basis for order.