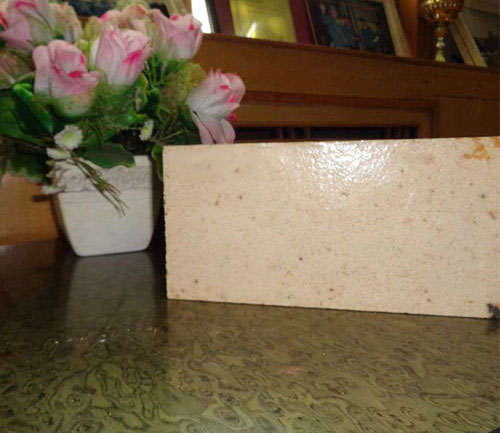

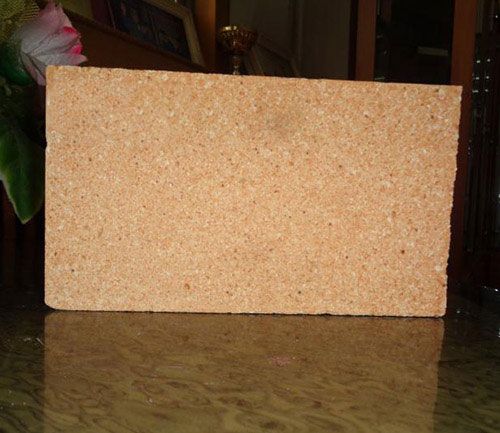

Feature:

High refractoriness under load temperature, good thermal shock stability, good erosion of chemical slag(liquid) resistance etc.

Al2O3% ≥48% silica-alumina refractory brick, called High alumina brick. It is usually classified into 3 grades. Al2O3≥75%, 1st grade, Al2O3 % between 60-75%, 2nd grade, Al2O3% from 48-60%, 3st grade. Anti-Spalling High Alumina Brick is produced by adding the certain amount of ZrO2 content based on the common high alumina brick to increase the anti-spalling of the brick performance.

Usually as working line used in limestone kiln, electronic arc furnace, blast furnace, hot stove etc. Industry furnaces.

|

Item Brand |

Al2O3 (%)≥ |

A. P. (%)≤ |

C.C.S. (MPa)≥ |

R.U.L.@ 0.2MPa & Ta(℃) ≥ |

T.S.R.at @1100℃ & cool waterTimes≥ |

Refractoriness ℃≥ |

|---|---|---|---|---|---|---|

|

anti-spalling High Alumina refractory brick |

||||||

|

HXYRS-70 |

70 |

22-25 |

45 |

1470 |

20 |

1790 |

|

HXXYR-76 |

76 |

22-25 |

55 |

1500 |

25 |

1790 |

|

Chemical bonded high alumina refractory brick |

||||||

|

HXCLZ-8 |

75 |

23 |

54 |

1500 |

---- |

1790 |

|

High alumina refractory brick |

||||||

|

HXLZ-75 |

75 |

23 |

54 |

1500 |

---- |

1790 |

|

HXLZ-65 |

65 |

23 |

49 |

1470 |

---- |

1790 |

|

HXLZ-55 |

55 |

22 |

44 |

1450 |

---- |

1790 |

*They are typical values in this table, not a basis for order.